Advantages:

This system has many advantages over Motorised Roller Systems – mechanically, electrically and functionally.

Mechanical Advantages:

- From just two motors, this system offers a range of powers far exceeding that of most motorised roller systems. Making this suitable for almost all conveying requirements.

- No gears mean longer life, greater efficiency and almost silent running.

- Common motor external dimensions mean the two motors can be exchanged with ease.

- Motors are not specific to a track width or conveyor speed. Hence much reduced spares stock required.

- Round Belt and Poly V drive options for optimum drive selection.

- Motors sit within the conveyor width and beneath the rollers. They are hence protected from external damage and impact loads.

Electrical Advantages:

- Fully wired up at the factory to save time on installation.

- 35A capacity of power cables means fewer points to introduce power.

- Use of the ‘Branch Monitor’ allows single point programming meaning access to control cards isn’t even necessary to set up, re-configure and control the conveyor.

- A truly scalable control platform. From the simplest system requiring just a few cards, to single point control and programming with a ‘Branch Monitor’ to a full PLC interface with an Ethernet IP connected ‘Fieldbus Branch Monitor’. All using the same parts, so no obsolescence if upgrading/expanding a system.

- Six smart inputs and outputs per card allow ancillary devices to be connected.

Functional Advantages:

- Remote single point programming for all zone functions and speeds.

- Upgradable firmware so future releases and new features can be added to existing conveyor systems.

- Up to 255 zones in a single ‘branch’.

- Extensive set of features allow functions such as speed control, single/slug release, fast single release, long box detection, jam timers, missing load detection, half speed at rear of queue, transfer location control and dual speed zones.

- Capable of zero line pressure accumulation in both directions.

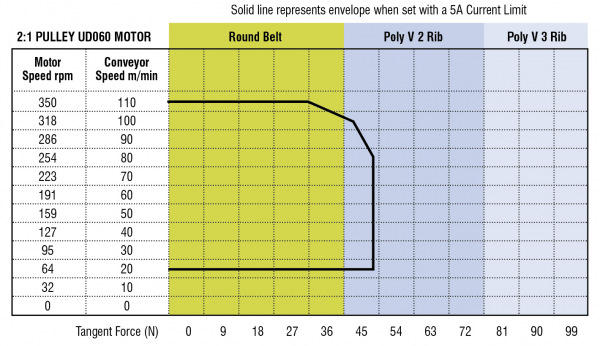

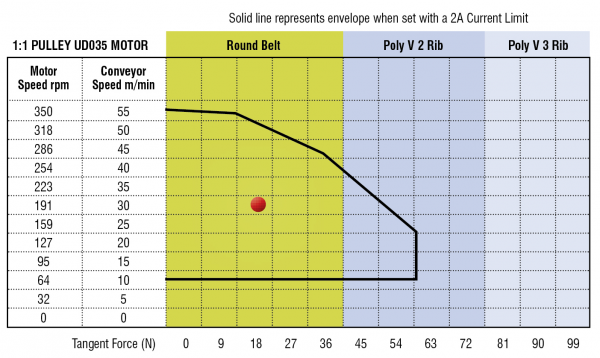

Choice of Motor Powers

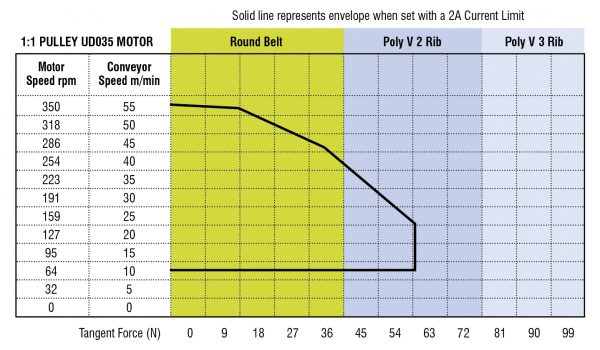

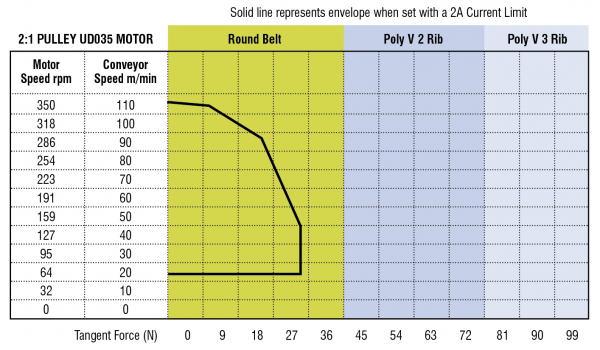

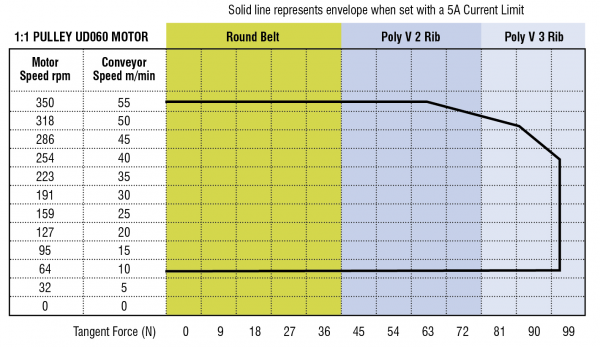

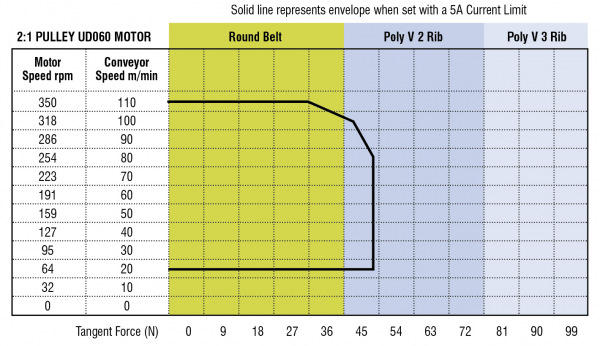

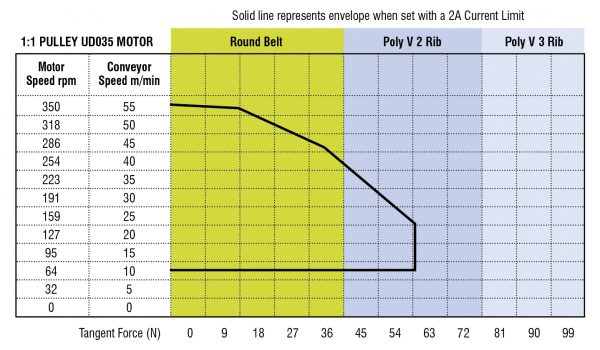

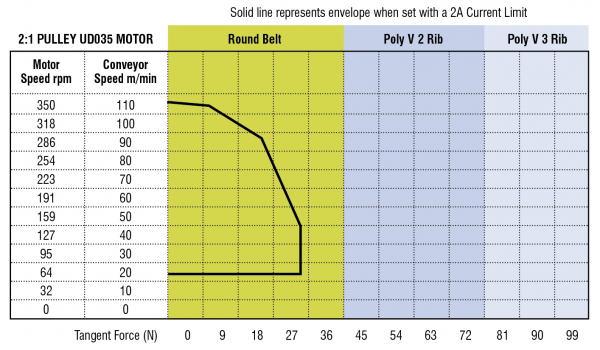

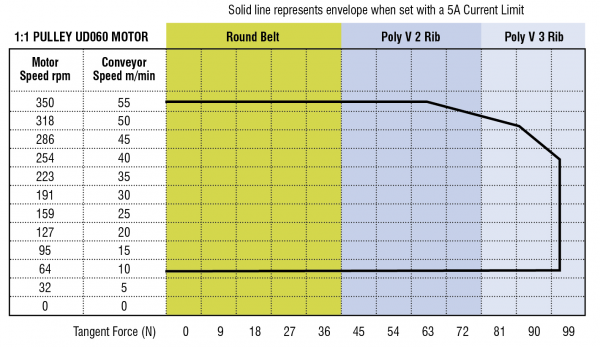

The ZoneLogixPRO™ system offers two motor power options.

Selection of which motor power best suits the application depends on the load being conveyed, the speed at which it is to be moved, how many rollers the motor has to drive in the ‘zone’ and the drive transmission between rollers.

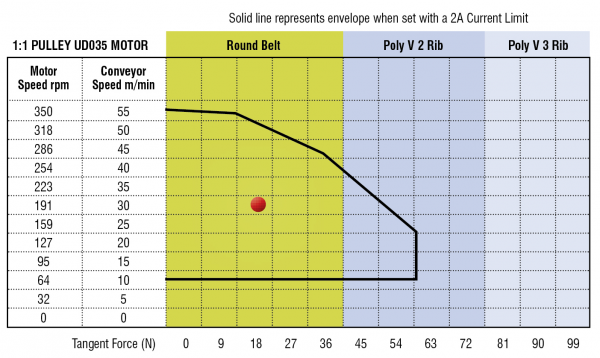

Typically a 20kg good quality cardboard box travelling on roller conveyor at 30m/min in a zone of 10 rollers with Round Belt drive would require 18.7 N tangential force. This would be powered using a 1:1 ratio drive pulley and the UD035 Motor. This falling here on the following charts.